Workpiece carriers and base frame tool

Workpiece carriers

Workpiece carriers

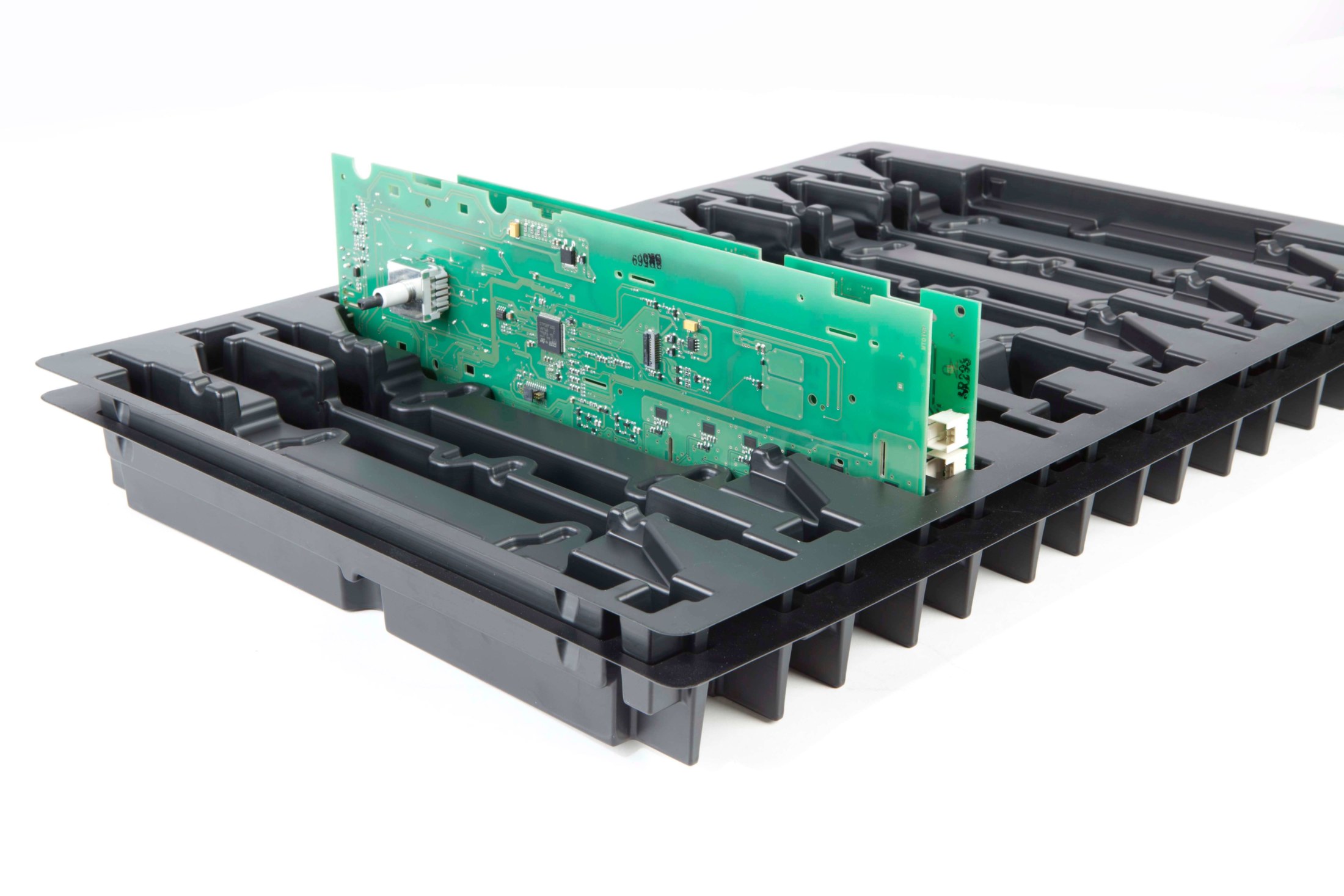

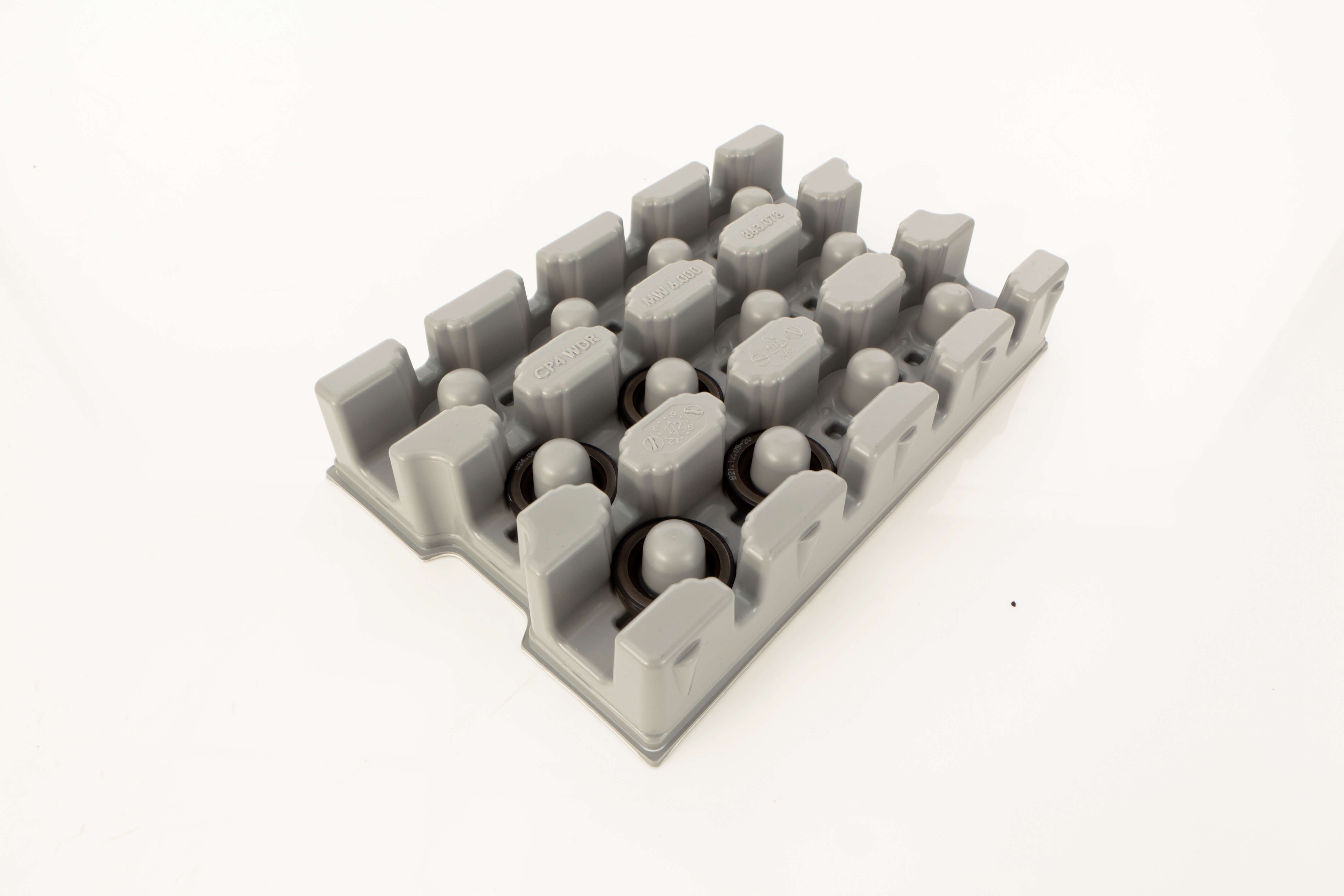

Stackable self-supporting workpiece carriers made to measure

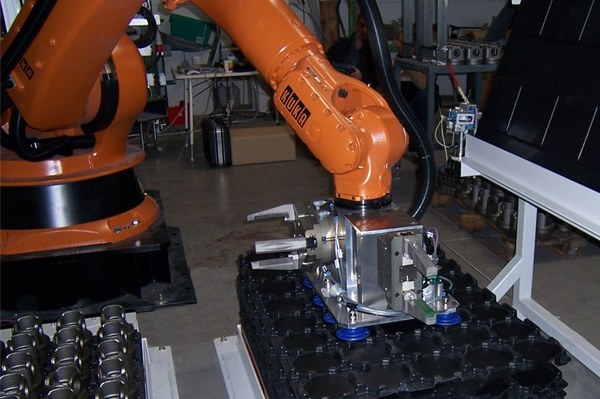

In cooperation with our customers, we develop plastic frame systems that are precisely matched to your production and assembly conditions or your automation technology. Just let our technical advisors know your requirements for the equipment used or your automation technology. In this way, you develop thermoformed frame systems in cooperation with our design department and your technical planning department, which meet all the requirements of your automation and ensure your continuous production without disruptions.

Base frame tool with workpiece carrier and trays for your automation

For our standardised frame tools, we design the precisely fitting inlay tool for your product, which is built into our frame tool. The tool-facing outer frame enables the use on automated production and assembly lines also due to exact reproducibility. Identical outer frames can be used again and again for different inlay tools.

The benefits of swissplast workpiece carriers and base frame tools:

Dust and splash-proof

Additional protection through standardised but also contour-specific covers

Anti-twist protection

- Visually through a colour strip

- Mechanically, for example, by a non-symmetrical corner

- Label pockets (1-, 2- or 3-sided)

- Labelling of the workpiece carrier

- Lettering inserts in the mould for customer logos, article numbers or similar

- Pad printing

- Hot stamping

- Screen printing

Identification features can be positioned individually

- Barcode labels

- RFID transponders

Possible sizes of workpiece carriers and base frame tools:

From 400 x 300 mm

up to 1200 x 1000 mm

Base frame tool from swissplast – ideal for your product

The use of base frame tooling with a workpiece carrier has a number of advantages: On the one hand, swissplast manufactures the tray for your product individually and precisely to fit. This enables optimum and safe handling of the product. On the other hand, the basic frame tool is adapted to your production conditions and can therefore be easily integrated into the workflow. Furthermore, the workpiece carriers and trays are made of high-quality plastic from swissplast. This enables easy integration into your production system. At the same time, the trays are stable and resistant to chemicals, so they have a long service life. In the interest of environmental protection, but also to reduce costs, we use a lot of recycled plastic. To this end, swissplast has been producing in a CO2-neutral way for many years.

Plastic workpiece carriers from swissplast – stable, durable, inexpensive

How do you move and store your products in your production facilities? Plastic workpiece carriers or a plastic tray are the ideal solution for storing small and medium-sized items. Compared to other materials such as wood or metal, the use of plastic trays has great advantages: On the one hand, plastic workpiece carriers are more stable and at the same time lighter than wood. They are impact-resistant and always return to their original shape. On the other hand, plastic parts are very light and therefore superior to metal parts. In addition, there is the short production time and the low production costs for plastic workpiece carriers. Our thermoforming process also compares very favourably with other plastic production methods. Thus, we create inexpensive, robust and durable trays and workpiece carriers made of plastic for your individual use.

Plastic workpiece carriers – standardised or customised

In the work area of base frame tools, workpiece carriers and trays made of plastic, we have a lot of design freedom. We can offer you standardised trays for your production, available in the sizes 400 x 300mm, 400 x 400mm, 600 x 400mm, 800 x 600mm, 1000 x 600mm and 1200 x 800mm. However, if you prefer other dimensions in your company, we can also react accordingly and produce workpiece carriers according to your individual dimensions. Of course, the quality of the plastic workpiece carriers from swissplast always remains at the same high level – regardless of the dimensions. You get the product you need for your production. Please feel free to contact our experts. We will advise you on the perfect dimensions for plastic trays and workpiece carriers.

swissplast plastic trays and workpiece carriers for your business

The production of trays and workpiece carriers made of deep-drawn plastic is part of our core business. We have been supplying our customers with high-quality plastic trays for many years. We therefore have a great deal of expertise in this area of plastic processing. In the production of precision-fit workpiece carriers and base frame tools, swissplast always focuses on environmental protection. We use recycled plastics and work with an enormously low error rate, which in turn reduces rejects and the loss of materials. In addition, swissplast has been producing in a CO2-neutral manner since 2013. In 2021, the compensation of CO2 emissions was also extended to raw material production, customer contact and recycling. In this way, swissplast is also pioneering the production of plastic trays and plastic workpiece carriers in the plastics industry.

Other workpiece carriers