Industries

Info

Moulded plastic parts, plastic cladding & plastic enclosures

Durable or delicate? With swissplast moulded plastic parts and casings made of thermoplastics, you are not making any compromises! The plastic components for vehicle trims, dashboards and wheel covers convince through design as well as durability.

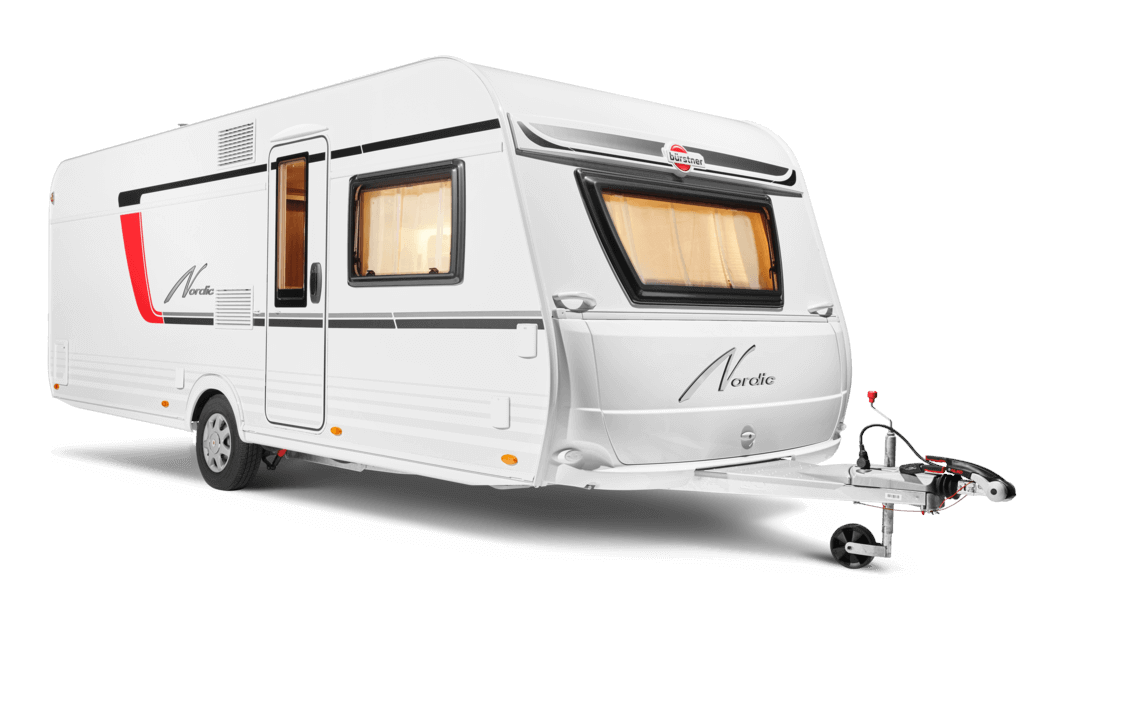

High-quality plastic parts & components for commercial vehicles, caravans or construction machinery

Reliability meets innovation: as a proud market leader, swissplast supplies regional and international customers in many different industries: Our moulded plastic parts directly from the manufacturer complete and protect construction machinery, but are also used to equip caravans or campervans. These sectors already benefit from the low weight and optimal shape of the material. Moulded plastic parts are therefore increasingly used in plant and mechanical engineering.

Our competence for moulded parts made of plastic:

- Unique through design and optics

- Moulded plastic parts with special material-specific properties

- Diverse surfaces and special contours

Special solutions for assemblies by assembly / bonding

- Functional system components

- Weight-reduced assemblies for e-mobility & machine construction

Materials: all standard thermoplastics but also engineering plastics in material thicknesses from 2mm to 14mm, e.g. for metallised surfaces, use of ABS PMMA for high-quality surfaces as well as PC or PMMA as transparent materials

Plastic casings with deviating and standard dimensions

We use the plastic deep drawing process to satisfy economic and aesthetic demands: Individual adaptations, e.g. for plastic moulded parts for hot water boilers, in diameter or plastic colour are no problem for swissplast. We manufacture both individually shaped workpiece carriers and standardised plastic moulded parts for commercial vehicles exactly to your specifications using efficient thermoforming. Large quantities do not affect our ability to deliver whatsoever, which is why we also manufacture moulded plastic parts for motorhomes.

Full service from swissplast: from the sketch to the finished plastic cladding

Our factories produce moulded plastic parts and components exactly according to the wishes of our customers. We use the maximum moulding area of 3000 x 2000 x 1000mm for vacuum moulding of very large plastic claddings and plastic enclosures.

From swissplast you get everything from a single supplier: we take care of the creation of the sketch and work the design proposal of the plastic moulded part into our in-house 3D CAD system. After approval of the prototype and the samples, we produce the plastic enclosures in series or individually according to your specifications – at the end of this production process, you will have high-quality and design-oriented plastic enclosures as well as precisely fitting plastic mouldings. On request, we can also arrange separate delivery solutions that can be integrated into your work processes. As a market-leading manufacturer of plastic moulded parts, we meet your requirements both in terms of the quality of the products and our comprehensive service, offering suitable solutions for all areas of industry.

swissplast – Plastic mouldings from Swiss and German production

We are a leading manufacturer of moulded plastic parts in Switzerland and Germany and supply customers throughout Europe. Our main area of business is the manufacturing of plastic parts by deep drawing. In this process, a plastic sheet is heated, melted, placed over a stencil and shaped in this way. The process is particularly versatile, as a large number of different plastic parts can be produced in this way. The limit is the dimensions of our deep drawing machines, namely 3000 x 2000 x 1000mm. In these dimensions, we as a manufacturer of plastic parts can meet every demand. We stand for transparent communication, so that every plastic moulded part is produced in close consultation with our customers.

In which industries does swissplast operate?

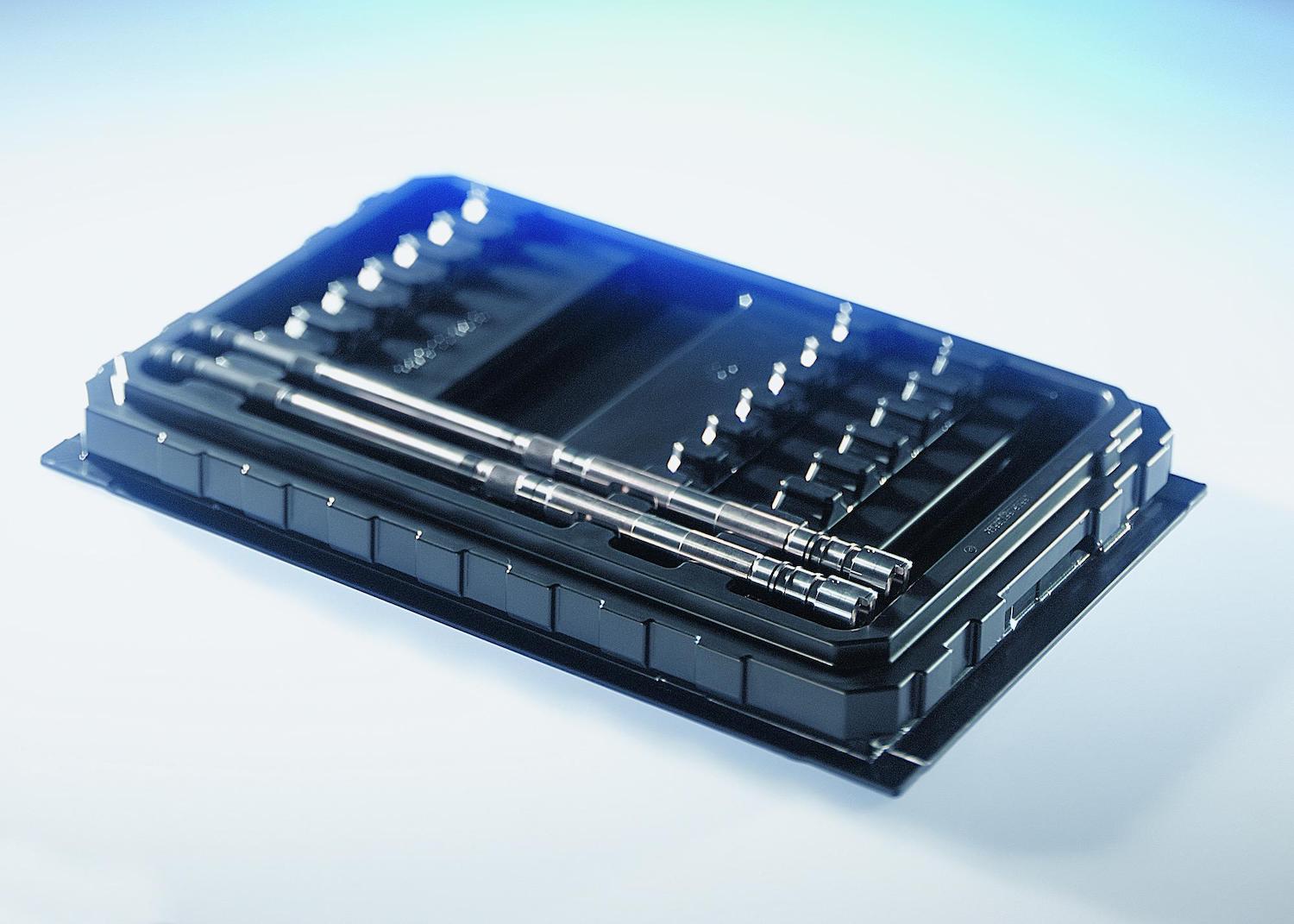

swissplast has a wide range of activities and supplies customers in many industries with plastic parts. In the automotive sector, for example, we manufacture robust technical components such as covers, cladding, exterior trim, interior trim or fittings. These are used in electric cars, special vehicles, motorhomes or construction machinery. In the public transport sector, we mould fire-resistant large-area covers and cladding made of plastic for buses and trains. Our plastic parts are also used in the industrial sector, for example in machine and plant construction, in sanitary engineering or in medical technology. Here, too, there is a demand for cladding and covers that can withstand daily stresses and strains. Another core area of our work is the production of plastic packaging for workpieces of any size. Also in this area, we are almost unlimited in our possibilities. Please feel free to send us an enquiry!

swissplast is your reliable manufacturer for plastic parts

With one plant in Switzerland, three plants in Germany and now over 200 employees, swissplast is one of the largest deep drawing companies in Europe. We can look back on a successful history in which we have always grown. Our plastic products and technical components are used in all industries and economic sectors. In addition, swissplast sets an example in the plastics processing market in that we have been a climate-neutral company since 2013 and have also been offsetting the CO2 emissions from raw material extraction, delivery and recycling since 2021. This leading role in sustainability is an important part of our company philosophy. So, if you are looking for a plastic moulding manufacturer with sustainable production in Europe, feel free to contact us.

Our industries