Plastics technology

Technology

Plastics technology from Switzerland and Germany

swissplast stands for the highest and most modern plastics technology from Swiss and German production!

Our tool and mold making services include the manufacture of component prototypes, test and pre-series tools, series tools for thermoforming and all types of operating materials. swissplast processes all types of plastics, as well as aluminum.

We manufacture plastic processing products in our own tool shop and use the very latest CAD-CAM-CNC technology. We procure aluminum moulds internationally from established and innovative toolmakers with a long tradition and state-of-the-art plant technology. We carry out the necessary maintenance and repairs in-house in our tool shop.

Consulting

We manufacture plastic according to your wishes

As an owner-managed plastics technology company, uncomplicated, direct communication with customers, suppliers and partners is very important to us. swissplast processes plastics and thermoplastics exactly according to your specifications: whether tools, assemblies, prototypes or small series – we are pioneers in the thermoforming of plastics.

Plastics technology at swissplast

Our ambition is to always be at the cutting edge of plastics technology for our customers: Not only in the processing of plastic, but also with knowledge of the semi-finished products available on the market. In addition to standard colors, which can be reproduced according to RAL, Pantone or NCS, we also manufacture plastic in technical decors such as carbon and metallic design. Or natural colors such as marble, granite, stone, wood decor, etc.

Our ambition is to always be at the cutting edge of plastics technology for our customers: Not only in the processing of plastic, but also with knowledge of the semi-finished products available on the market. In addition to standard colors, which can be reproduced according to RAL, Pantone or NCS, we also manufacture plastic in technical decors such as carbon and metallic design. Or natural colors such as marble, granite, stone, wood decor, etc.

A wide variety of requirements are placed on the surfaces of molded parts, depending on the area of application. For example, scratch resistance, gloss or grain. Our suppliers and their products impress with improved stress crack resistance and a wide range of surface finishes from matt to high-gloss.

Plastics technology from swissplast includes innovations such as specially developed soft “Softfeel” surfaces, which are equipped with a specially developed soft COEX top layer. This plastic has outstanding properties in terms of thermoforming and recycling; a sign of swissplast’s international and future-oriented focus.

The plastic molded parts and thermoplastics from our manufacturers demonstrate particular qualities in outdoor applications, for example. They can be exposed to direct weathering such as sunlight, cold, heat, wind and precipitation without any problems.

In order to meet the high demands of different industries, special multilayer sheets have been developed for use in plastics production.

These plastics include

- Electrically conductive

- resistant to high temperatures

- UV-resistant

- Self-extinguishing according to fire behavior S 4, SR 2, ST 2

- Self-extinguishing according to DIN 5510

Plastic thermoforming / deep drawing

Plastics technology is our strength: sophisticated plastic parts

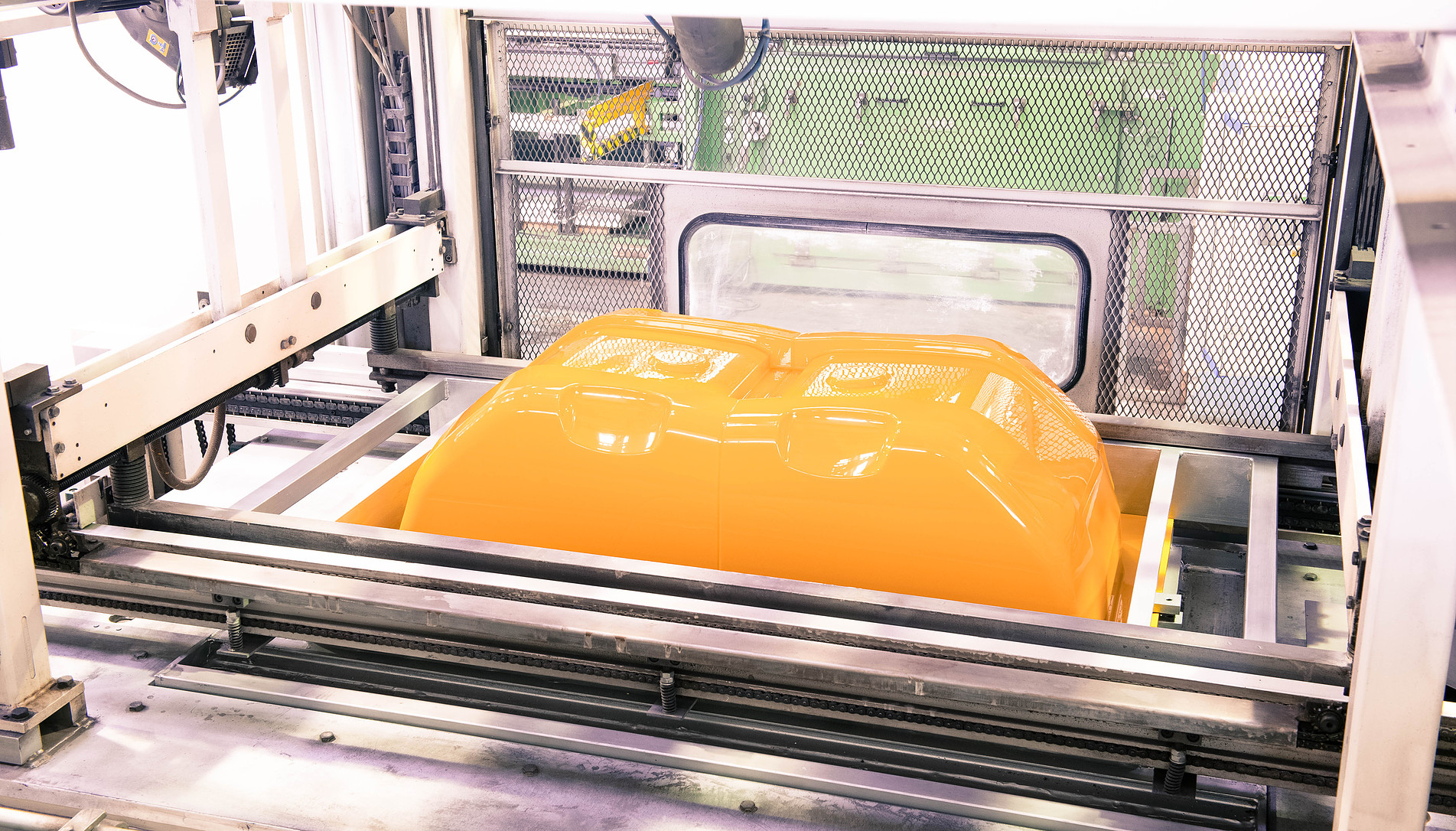

As a leading supplier of plastics technology in Central Europe, we focus exclusively on the thermoforming of plastics.

Our high-quality thermoforming trays and plastic parts with a forming area of up to 3000 x 2000 x 1000mm are manufactured using the latest machinery to ensure flawless results. Take advantage of our expertise in plastics technology as early as the development phase.

We will be happy to advise you on how to check your individual design for cost-effective production during the preparation phase. This guarantees flawless thermoforming of technically high-quality plastic molded parts, which supports your market success.

What happens after thermoforming?

Our work does not end with the thermoforming process, our plastics technology is so much more: although thermoforming is our core plastics technology, post-processing using CNC milling and assembly production are also part of our repertoire. Last but not least, we ship the products to our customers on time.

Plastic milling using CNC

Plastic milling using CNC

Precise machining of plastic parts with CNC-controlled 5-axis milling centers of the latest technology is the guarantee for high-quality thermoformed parts from our plastics processing department. This brings us one step closer to the thermoformed plastic part on the way to the finished product that the customer wants.

subassembly production

subassembly production

We glue, weld and assemble additional products to the plastic parts on a customer-specific basis: For example, locks, duptaras, electrical components and much more. In this way, a further work step takes place in our production. We can then deliver the finished product to the customer and all that remains to be done is installation.

On-time shipping

On-time shipping

All our customers are different and we know that what is right for one is not necessarily right for another. Flexibility is, of course, key to supplying our customers in the way that is right for them. For years we have been offering on-time, on-belt (JIT) or even workstation (JIS) delivery solutions.

Interesting facts about plastics technology

swissplast is a leading company in the plastics technology sector. Thanks to our state-of-the-art processes, we manufacture plastic parts for industrial purposes. These include, for example, packaging, trays, formwork, cladding and covers. Each individual product goes through the process of product design, production and refinement. When selecting the plastic, we can determine which properties the finished plastic product should have later on: Durable and robust plastic parts for outdoor use on vehicles or delicate ESD plastic containers for electrical components? Both options – and many more – can be realized with our methods. Send us an inquiry about our plastics technology now and we will provide you with comprehensive advice.

Deep drawing, also known as thermoforming or vacuum forming, is an excellent way of processing plastics. In addition to the reliable repeatability of the forming process, the method is also cheaper and faster than similar plastic technologies. In contrast to metal, wood or cardboard, plastic is also very light, but extremely robust and resistant to water, chemicals and fire. The size of our plastic parts also speaks for itself: since 2022, we have been able to produce plastic workpieces measuring up to 3000 x 2000 x 1000 mm. This means that our plastic parts are even more versatile and can also be used as cladding or packaging for large machines, vehicles or workpieces.

The plastic technology of thermoforming opens up a wide range of possibilities for how we manufacture our products. When selecting the plastic, we can fall back on various new or recycled generates. In addition, the color of the plastic can be changed to match the corporate design of any company. The shape of a plastic part is determined by the template, which we design in close consultation with you. With our precisely designed templates, we ensure a high degree of accuracy for the plastic parts to be produced. After thermoforming, we can make notches, holes or other refinements to the workpiece using CNC milling. Let our professionals advise you on whether plastics technology from swissplast can also help your company.

Thermoforming as a plastics technology offers numerous advantages in packaging production. The process is efficient and enables the rapid production of customized packaging in large quantities. A wide variety of materials can be used, such as PVC, PET or PP, which offer specific properties such as transparency, stability or flexibility, depending on requirements. Another advantage is the high precision of the process, which makes it possible to create complex shapes and details that perfectly enclose the product. Thermoforming is also a cost-effective and resource-saving plastics technology, as very little material is wasted. This versatility makes it the ideal solution for numerous industries.

In addition to thermoforming (deep drawing), additional plastic techniques are often used to further process or refine packaging and components. CNC milling is used to integrate precise cuts or complex shapes into thermoformed parts, especially for industrial applications. Printing techniques such as screen or digital printing are used to apply logos, text or graphics to the surfaces of packaging. Drilling and punching techniques are also common methods for creating holes or special recesses in the components. This combination of thermoforming with post-processing enables highly individualized, functional and aesthetically pleasing products.

Despite some challenges, thermoforming as a plastics technology offers valuable opportunities for optimization. For complex or intricate shapes, the process still allows the creation of clear, functional designs, while alternative techniques can be used as a supplement for particularly detailed components. The targeted adaptation of material thicknesses allows flexible and stable packaging to be developed. In addition, the selection of specialized plastics offers the opportunity to find tailor-made solutions for specific products. Although tooling costs can be higher for small series, these investments ensure high precision and quality, which promotes efficiency and cost-effectiveness in the production process in the long term. In comparison with other manufacturing processes within plastics technology, thermoforming therefore often performs better than average.

swissplast offers thermoformed products in impressive dimensions of up to 3000 x 2000 x 1000mm. These extensive dimensions make it possible to produce even large, complex plastic parts that are frequently used in the automotive industry, mechanical engineering and other industrial sectors. Thanks to the flexible design of the products, specific customer requirements can be precisely implemented. With this production capacity, swissplast offers tailor-made solutions for demanding projects that require high quality and durability, thus setting standards in plastics technology.

Further topics