68 new parts in just 16 weeks

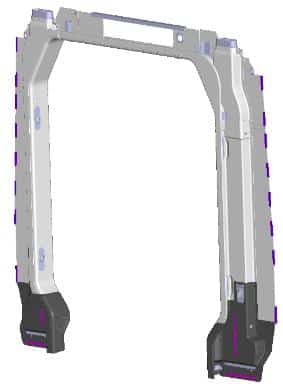

The swissplast group realized the complete interior cladding for a European streetcar project of a well-known train manufacturer (Stadler Rail) – from side and passageway cladding to rear wall cladding.

Only 16 weeks passed between the signing of the LOI and the delivery of all parts for the first train composition.

Engineering in record time

In just 7 weeks, our experts developed and designed 68 complex components including 3D and 2D data creation – with the highest demands on vertical integration, including integrated ventilation guidance.

Toolmaking in parallel processes

At the same time, an impressive 17 cooled aluminum deep-drawing tools, high-precision CNC 5-axis trimming tools and a large number of gluing and assembly devices were created.

Special profiles & materials according to standard

Customer-specific aluminum extrusions, rubber profiles, fire-certified semi-finished products (EN 45545) and hundreds of sheet metal attachments – all perfectly coordinated and ready for component assembly.

Start of series production without detours

Due to the very tight schedule, the sample phase had to be dispensed with – and yet every part fitted technically right away. Compositions 2 and 3 were also delivered in full two weeks later.

Our recipe for success:

With two experienced project managers and proven partners in the supply chain, the swissplast group efficiently guided the project to its goal.

Thanks to personnel support from other plants, products could be run in at the same time in the CNC department and assembly was completed smoothly. simple / fast / reliable.